Understanding the Evolving Landscape of IVD Device Compliance and Safety

04 Sep 2025

Managing the Compliance Curve in Next-Gen Diagnostic Devices

The world of in vitro diagnostic (IVD) devices is undergoing significant transformation. With growing technological integration, a shift in consumer behavior, and a changing regulatory landscape, manufacturers must now navigate a far more complex path to compliance than ever before. At the forefront of this evolution is Intertek’s deep technical expertise in testing, certifying, and supporting medical and laboratory equipment across global markets.

The Rise of IVD Devices in a Post-Pandemic Era

IVD products have seen a notable surge in development and market penetration, driven in large part by the COVID-19 pandemic and a broader societal shift toward proactive health monitoring. Today’s consumers are not only seeking diagnostic tools when symptoms emerge but are increasingly interested in early detection and chronic disease management through accessible, user-friendly diagnostics.

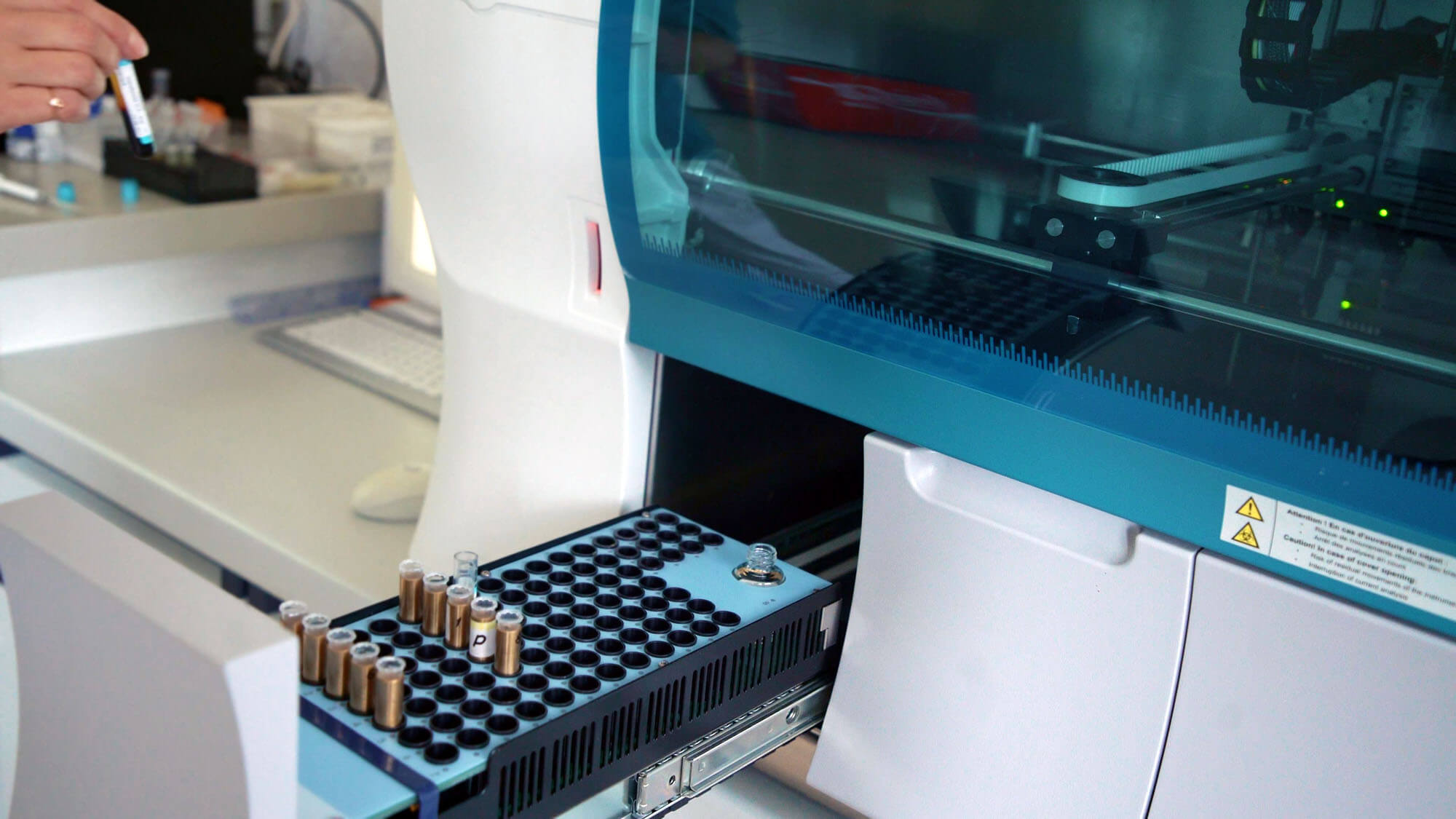

A notable trend in this space has been the increase in point-of-care testing devices. These systems, designed for use near the patient often in a home environment have become essential. COVID-19 test kits are a clear example. Designed for ease of use and speed, they reflect broader demands around usability, connectivity, and responsiveness. Consumers now expect seamless access to their health data, often through apps and connected devices. This demand has ushered in technologies such as AI integration, Internet of Things (IoT) capabilities, and fully automated lab analyzers incorporating robotics. These high-throughput machines can process large volumes of samples efficiently, but they also introduce a new layer of complexity in terms of safety, risk management, and compliance.

Regulatory Complexity: Choosing and Applying the Right Standards

Navigating the regulatory frameworks that govern IVD devices can be daunting. These products often fall under multiple jurisdictions, each with their own set of expectations, approval processes, and recognized standards. For manufacturers, success starts with a clear definition of the device’s intended use. A critical early step is determining who will use the device and where. Will it be used by trained professionals in a clinical setting? Or by laypersons at home including children and elderly users? These decisions directly influence which standards and requirements must be applied, from safety and usability to data privacy and performance.

Different countries recognize different regulatory standards. For instance, the U.S. FDA offers a list of recognized consensus standards, while in Europe, harmonized standards under the In Vitro Diagnostic Regulation (IVDR) guide conformity. Across jurisdictions, there is a consistent expectation that manufacturers demonstrate alignment with the “state of the art.” That may require going beyond existing standards, some of which may be outdated and referencing more current literature, clinical data, or supplementary testing.

Modern IVD devices increasingly incorporate complex technologies such as lasers and robotics. These elements may trigger the need for additional standards to protect operators and service personnel from risks such as exposure to laser radiation and/or robotic movements. While the IEC 60825 series has a focus on the safety of laser products, safety related controls protecting against injury may have to be designed to meet the required reliability level by applying functional safety standards such as IEC 62061, IEC 61508 or ISO 13849-1.

Early Considerations for Design and Compliance

When designing an IVD product, especially those intended for non-professional users, certain hazards become more relevant, such as exposure to hazardous chemicals, biohazards, or flammable substances. Standards such as IEC 61010-2-101 provide guidance on how to mitigate these risks through:

- Markings and Labeling: For example, equipment using biohazardous materials must feature clear, visible biohazard symbols in key areas like sample zones and waste containers.

- Documentation and Instructions: Installation, operation, and maintenance guides must clearly outline how to safely manage risks, especially where inherent construction-based protections aren’t feasible.

- Constructional Requirements: While fewer in number, requirements exist around features like over-temperature protection and the use of interlock systems for access control.

In some cases, devices may need to comply with multiple “particular” standards. A fully automated analyzer that includes heating elements or centrifuges might also require compliance with IEC 61010-2-010 (for heating materials) or IEC 61010-2-020 (for centrifuges). This reinforces the importance of defining intended use, conducting thorough risk assessments, and mapping out applicable standards early in the product development process.

The Importance of Documentation in Risk Files

When submitting an IVD device for testing or certification, the risk management file becomes a central document for review. According to IEC 61010-2-101, manufacturers must document a risk assessment especially for hazards not explicitly addressed by either the general or particular standards.

This requirement reflects the reality that standards may not always keep pace with emerging technologies or novel applications. A robust risk file should demonstrate not only that risks have been identified and mitigated but also that control measures have been verified and validated.

Testing laboratories will closely examine this documentation to confirm that risks are reduced to a tolerable level and that each mitigation has been appropriately implemented.

Early Preparation is Key

The regulatory landscape is dynamic and ever evolving. Early preparedness is key. Manufacturers should define target geographies, understand applicable standards, and begin documenting their compliance strategy as early as the design phase. This approach reduces delays, minimizes the risk of non-compliance, and ultimately ensures a safer product for end users. From usability engineering to software integration, performance standards to labeling, IVD manufacturers face an intricate but navigable path to market provided they take the time to plan, assess, and document thoroughly. As IVD devices continue to evolve in scope and sophistication, so too must the strategies that support their safe and effective deployment across the globe.