IMO2020 – Is it all Plain Sailing?

22 May 2020

Relevance of ISO 8217 following IMO 2020

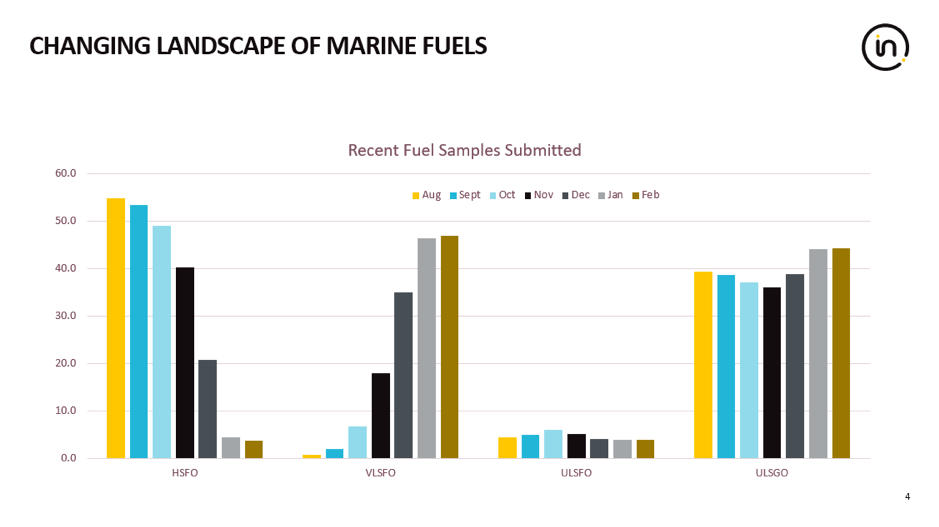

The 1st January 2020 marked a significant day in the world of shipping when legislative reform saw the global sulphur cap for marine fuels reduced from 3.50 % to 0.50%. This monumental change is now generally referred to as IMO 2020.

Over a very short period of time, the industry moved away from using the familiar High Sulphur Fuel Oils (HSFO) and replaced them, in the main, with Very Low Sulphur Fuel Oils (VLSFO) with HSFO being used, and permitted, only on vessels fitted with abatement technology (scrubbers).

The industry standard that applies to bunker fuel, is ISO 8217. This is a commercial standard covering both residual fuel and distillate fuel.

An assessment has been completed on the test data from VLSFOs purchased during Q1 2020, and it shows that the properties of VLSFOs range from that of a typical distillate fuel to that of a typical residual fuel. As a result, the question has been asked on numerous occasions whether the current ISO 8217 specification is still suitable for today's fuels.

In the lead up to IMO 2020, the International Organisation for Standardisation (ISO) produced the Publicly Available Specification - ISO PAS 23263.

This document highlighted that specific consideration should be given to Kinematic Viscosity, Cold Flow Properties, Stability, Ignition Characteristics and Catalyst Fines. It did not include additional specifications for 0.50% mass fuels, but it did recommend that VLSFOs need to meet the ISO 8217:2017 specification.

So why is the relevance of ISO 8217 being questioned?

Firstly, we need to look at how marine fuel is ordered. Historically, procurement departments of shipping companies ordered HSFO against a viscosity specification, e.g. RMG 380, where 380 denotes the maximum allowed viscosity of the fuel (mm2/s). All other parameter specifications within ISO 8217 additionally have to be met for an RMG 380 fuel.

|

Parameter |

Unit |

Limit |

RMA |

RMB |

RMD |

RME |

RMG |

RMK |

|||||

|

Kinematic viscosity @50°C |

mm2/s |

max. |

10 |

30 |

80 |

180 |

180 |

380 |

500 |

700 |

380 |

500 |

700 |

Since the introduction of VLSFOs, the shipping community has continued to order fuel against the residual fuel viscosity specifications. However, in the majority of cases, the viscosity of the fuel bunkered is considerably lower than the viscosity of the fuel grade ordered.

Why is this?

In order to accommodate the maximum sulphur limit of 0.50 % mass, in many instances, HSFOs are blended with low sulphur components to reduce the overall sulphur level to 0.50% or below. This has the effect of massively reducing the viscosity of the product and, as ISO 8217 does not state minimum values for many parameters, VLSFOs with viscosities as low as 3 mm2/s have been seen in the market. This results in the vessel having to modify its fuel handling to reflect the characteristics of the fuel. There are several ISO 8217 parameters which have been affected positively by this change: reduced levels of carbon residue, reduced ash content and lower levels of catalytic fines. However, conversely, higher pour points have been observed.

Table 2.0 provides a comparison between HSFO tested in Intertek Lintec laboratories during the first three months of 2019 compared to VLSFO tested in the same laboratories during the first three months of 2020.

|

Parameter |

Unit |

Q1 19 HSFO Average |

Q1 20 VLSFO Average |

|

Kinematic viscosity @50°C |

mm2/s |

338 |

117 |

|

Density |

kg/m³ |

982 |

936 |

|

Acid number |

mg KOH/g |

0.4 |

0.7 |

|

Carbon residue |

mass % |

13 |

5.6 |

|

Pour point |

°C |

-4 |

10 |

|

Ash content |

mass % |

0.04 |

0.02 |

|

Al & Si |

mg/kg |

28 |

21 |

To understand the variability experienced with VLSFOs, we need to not only consider the average results but, also examine the variation in results as provided in Table 3.0. This data set considers fuel ordered against all viscosity grades stated in ISO 8217.

|

Parameter |

Unit |

Q1 20 VLSFO Minimum |

Q1 20 VLSFO Maximum |

|

Kinematic viscosity @50°C |

mm2/s |

2.75 |

736.9 |

|

Density |

kg/m³ |

833.3 |

1025.9 |

|

Acid number |

mg KOH/g |

<0.20 |

3.33 |

|

Carbon residue |

mass % |

<0.01 |

16.19 |

|

Pour point |

°C |

<-12 |

42 |

|

Ash content |

mass % |

< 0.001 |

0.136 |

|

Al & Si |

mg/kg |

2 |

156 |

If we concentrate solely on fuel ordered against the RMG380 specification, it can be noted that the only difference observed is an overall reduction in viscosity from 736.9 mm2/s to 395.4 mm2/s.

|

Parameter |

Unit |

Q1 20 VLSFO Minimum |

Q1 20 VLSFO Maximum |

|

Kinematic viscosity @50°C |

mm2/s |

2.75 |

395.4 |

|

Density |

kg/m³ |

833.3 |

1025.9 |

|

Acid number |

mg KOH/g |

<0.20 |

3.33 |

|

Carbon residue |

mass % |

<0.01 |

16.19 |

|

Pour point |

°C |

<-12 |

42 |

|

Ash content |

mass % |

<0.001 |

0.136 |

|

Al & Si |

mg/kg |

2 |

156 |

So, to answer the question……

We might find the next revision of ISO 8217 introduces new fuel grades and additional tests. However, in the meantime, given the variability of marine fuels in the current market, it is essential that fuels continue to be tested against the latest version of ISO 8217 in order to ensure environmental compliance, the safety of the crew and the safe operation of the vessel.

Tracy Wardell,

Global Technical Manager, Intertek Lintec

Tracy is Intertek Lintec's Global Technical Manager. She joined Intertek Lintec in 2011, having previously worked in the chemical industry, and has held positions as Operations Manager and Business Development Manager. Tracy now concentrates on the technical aspects of marine fuel, assisting customers with technical issues whilst heading the technical and customer service department of the business. Tracy holds a BSc in Chemistry.