Monitoring Pipelines for Microbiologically Influenced Corrosion

19 Aug 2014

Pipeline failure can have serious consequences in the oil and gas industry. Understanding and mitigating the causes of failure is a vital part of pipeline maintenance and is a valued service provided by Intertek.

Maintaining pipeline integrity is crucial in the oil and gas industry and when pipeline defects are detected, or pipeline failures occur, understanding the causes of these events is of utmost importance.

Internal and external corrosion is a key concern in maintaining a pipeline and ensuring it continues to operate safely and reliably. One cause of corrosion is microbiologically influenced corrosion (MIC) and as much as 40% of internal corrosion in the oil and gas industry may be caused by MIC.

Microbial growth tests and genetic tests can be used to quantify corrosion associated with microorganisms in pipeline samples. It is important to obtain comprehensive data in determining the corrosion mechanism in any given sample.

Physical and chemical tests, as well as microbiological/genetic tests, should all be used.

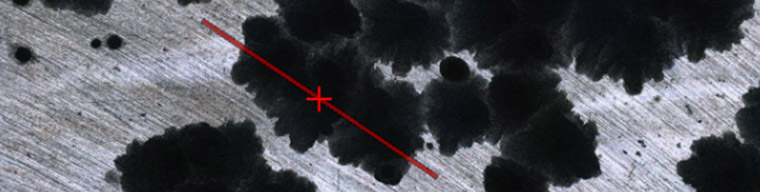

Microscopic examination of the morphology of corrosion pits, the chemical analysis of corrosion products, metallurgical analyses, microbiological analyses and knowledge of the operating conditions and fluid composition when the pipe was in service should all be considered when making a determination regarding the likely corrosion mechanism.