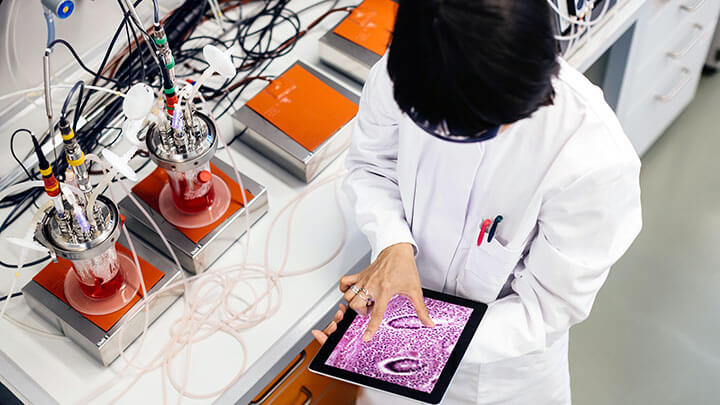

Morphology analysis and characterization.

Intertek offers advanced morphology analysis covering multiple techniques, for characterizing a wide range of materials. Experienced morphology scientists support research and development, failure analysis, quality control, troubleshooting and other complex scientific investigations.

Morphology analytical techniques available include microscopy, X-ray diffraction, thermal analysis, dynamic light scattering, porosimetry and interferometry. Services include elemental analysis of solid samples, impurities, and the identification of physical and chemical defects. Instrumentation is qualified to GLP and GMP standards, allowing the morphological data to be used in regulatory projects and pharmaceutical quality control.

Morphology techniques:

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-Ray Analysis (EDX)

- Transmission Electron Microscopy Analysis (TEM)

- Optical Light Microscopy (LM)

- X-Ray Diffraction (XRD)

- Differential Scanning Calorimetry Analysis (DSC)

- Thermal Gravimetric Analysis (TGA)

- Dynamic Light Scattering (DLS)

- Particle Surface Area Analysis and Porosity Testing

- Porosimetry

- White Light Interferometry

Types of systems studied:

- Materials, Polymers, Proteins

- Films and Coatings

- Geological and Mineral Core Samples

- Pharmaceuticals, Raw Materials and Ingredients

- Metals, Plastics, Ceramics, Glass, Food, Dust

- Contaminants, Unknowns

- Battery Electrode Morphology

Morphology applications:

- Polymorphism Studies

- Particle Size Analysis

- Crystal Habit Information

- Surface Roughness, Surface Structure, Surface Topography

- Internal Morphology and External Morphology

- Micro Elemental Characterization

- Contamination and Contaminant Identification

- Glass Transition, Melting Point Determination

- Crystallisation Temperature

- Decomposition Analysis

- Purity Determination

- Weight Loss

- Crystallinity

- Surface Area

- Internal Pore Volume

- Fluorescence

- Immunogold Labelling

- Cross-Sectioning

Additonal microscopy resources:

Applications:

- Pharmaceutical Stability Using XRD and Hot-Stage XRD

- Biophmarmaceutical Manufacturing Contamination

- And more

Microscopy Analysis Services: